This is a long over due project. Albin K. Longren was the first person to build and fly an airplane in the state of Kansas. Albin worked in aviation before well known names such as Beech and Cessna. The airplane I am modeling hangs in the Kansas State Historical Museum in Topeka Kansas. I have spent a number years studying Longren and his airplanes, the more I studied, the more I knew this was a project I wanted to work on. I plan to display my work on this project here on my web site. There will be times when the project goes idle and other times when progress will be made. I hope you check in at times and enjoy my attempt of reliving this part of aviation history. 10-10-2001

1914 Longren #5

This page out of a book by Richard Taylor tells a bit about the story of airplane #5 built by Albin Longren. It also shows a good side view of the aircraft. Albin was married to Dolly, a beauty pagent winner. She graced many of the photos along with Albin. The whole Longren story has captured my aviation imagination for years. It is time to start on this model. I hope to see it in the air, maybe flying out of the same field it flew from originally.

Click on small pictures for a better view

Here are a couple of shots scanned together to show you that the real airplane does exist. I hope to replace these photos with better ones before long. Check out that V-8 engine... real hot-rod for it's day. I have taken hundreds of photos at the museum and have calculated many of the measurements from these photos to come up with the drawings for my mock up that is being built in 1/8th scale. My R/C version is being built to 1/7th scale, 44 inch span on upper wing.

A long term modeling project of a famous Kansas airplane

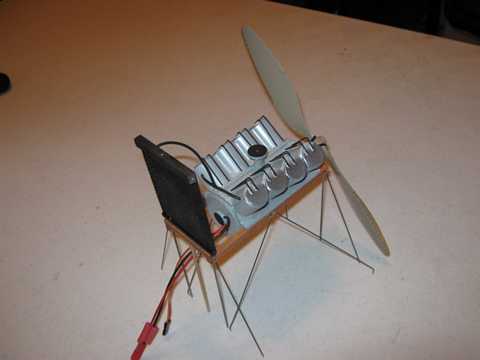

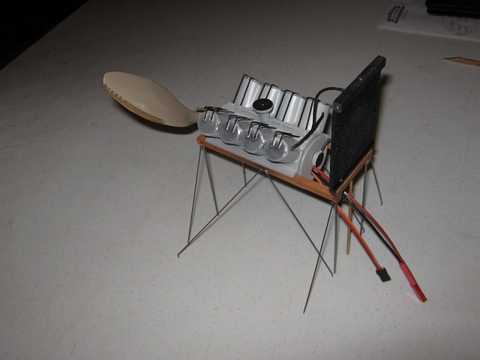

Cylinders glued on...then came the oil pan, heads, pushrods, and the interior mount for the electric motor.

Engine mount beams and radiator. Hoses were made of electrical wire insulation stripped of the copper. Motor and prop mounted, the electric speed control is inside the crankcase.

The motor carridge attachs at 13 lower points and 2 upper points.

Assembled again to work on the motor mounting points on the wings.

All appears about right...

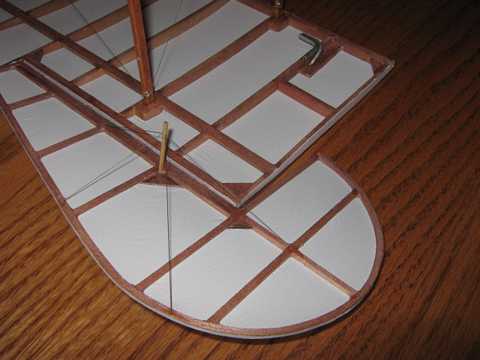

"Balsaloc" brand glue is brushed on the edges of the wood and then "Litespan" brand covering is lightly ironed on. Very careful not to induce warps into the very light wing structure.

The bottom is not covered. It was not possible to plan all the attachments in advance as there are no plans. I just work ahead the best I can, and constantly have to back up to make changes.

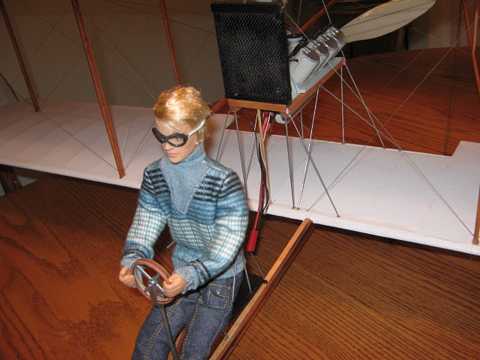

Motor is mounted, seat is built and in place, as is the steering control and laminated steering wheel. Laser cut bracing and steering wheel parts by modeler and friend Rod Taylor.

Various pics at different angles.

More pics...........

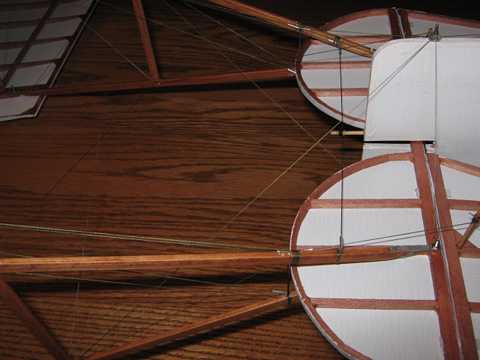

Pull - Pull controls are used, as was on the full scale. Standoffs are braced much as the real counterpart.

Rudder and Elevator servos are under lower wing. Aileron servo and radio receiver are mounted to the rear side of the radiator. Battery will attach to velcro just ahead of the servos.

As the original, the control cables route through metal tubing to stay clear of the prop and stabilize them from wind flutter.

Some of the tail group cable, structure and control.

These are huge elevators. I wonder how much travel they really had? Test flights will be made with caution.

10 inch tall "Ken" doll was nearly 8oz. After using aluminum wire and cotton for the body it weighed in just uner 3 oz. Googles were made from copper wire, elastic cord, and .010 clear acetate.

Full assembled and ready for flight...17.2 oz minus the battery.

4-25-2009 Ready for flight. Hope to fly this summer.

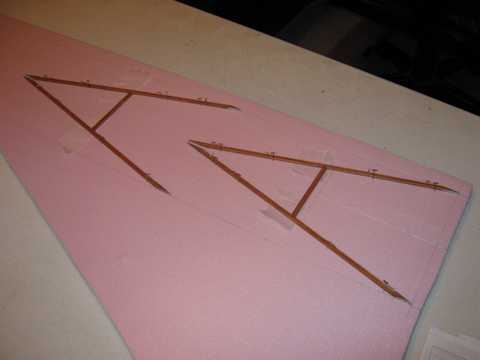

Homemade hot wire cutter used to make mock-up foam wings

Balsa ribs glued in place. This gives an easy place to glue to.

Rib spacing drawn on foam to get the dimensions all worked out.

Landing gear and motor in place.

This mock-up is invaluable as there are no plans or measurements for the model that is to be built.

Now on to the building of the actual R/C model

The wings were first. Laser cut ribs were aquired from fellow modeler Pat Trittle.

Aluminum attachment points are glued, riveted, and or screwed to the spruce parts.

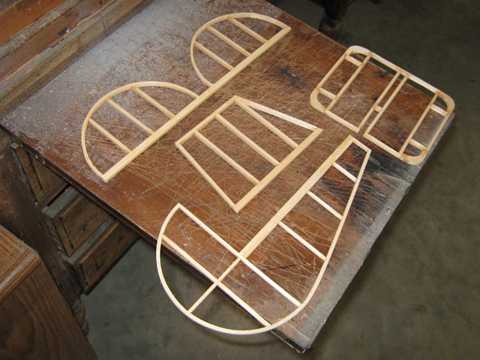

Curved tail parts were laminated using 1/16 balsa strips bent around patterns.

Tail longrons have center supports that are steel pinned in place. The tail must not move due to all the pull-pull controls.

Many jigs were built and used to bend and solder the many wire parts.

Taped together for a first look. This helps with solving many problems once you actually see it in one piece.

Landing gear is permantly attached. Hinging and r/c control is being sorted out.

The Hall-Scott 60 HP V8 is being built. Rolled balsa crankcase, vacum formed cylinders.....020 ABS over pvc pipe mold. The real motor turned 1400rpm and weighed approx 260 pounds.

Into the wind..........

and full throttle!

Landing at the museum to visit Albins full scale airplane.